Recently, we (the Western World) had a wintertime holiday season (take your pick of celebrations and spiritual affiliations) that traditionally includes the exchanging of gifts. Which presents a bit of a challenge during that gift, buying / wrapping / giving time of the year. We (Lisa and I), being the combination of two adult households, squeezed into half a house (900 feet ^2), have few unmet needs and even less room for non-essentials. Which means, for instance, no more furniture or superfluous kitchen appliances.

One morning, at the fire station, I was leafing through newspaper advertisement inserts (which I RARELY do), thinking about the gift dilemma, when destiny brought me to a page in the Target flyer. "Buy one, get two Roombas." Cue parting clouds, shaft of heavenly light, and choir of angels (or whatever - it's just a metaphor).

I've been thinking about getting a robot vacuum cleaner ever since I first heard about the Roomba. On one hand, my wife, Lisa, is a practical lass, and it's hard to sell her on gratuitous technology. I had to exert considerable charm to get a microwave in the kitchen (but now it's indispensable). But, on the other hand, what a perfect application for the domestic robot: a mindless dirty task. A robot doesn't get bored, have anything better to do, or argue. How can a gift that promises to clean the house and actually do the work not be appreciated? And I'd get two, one to use, and one to hack.

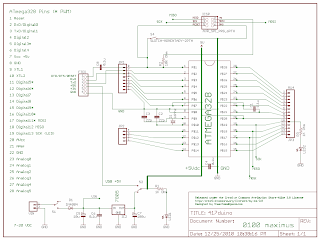

The Target offer was for a Roomba model 530 and model 400 for $299.99, a pretty good deal. What really excited me was that the maker of Roomba, iRobot, has made their robots hacker-friendly by exposing functionality via a serial port. The Roomba Open Interface provides access to the Roomba's sensor's and actuators through a serial communication protocol. A computer can be used to control the Roomba, either with a mini-din 7 cable tether, or wirelessly, using Bluetooth. I intend to build an interface cable to connect a 417duino to the Roomba serial port, and exert control over function and scheduling, the 417roombino.

The 530 came with a charging station (a "dock") and a couple of virtual walls that could be used to keep the robot out of certain areas, or away from potential hazards. A spare filter and cleaning tool for the spinning brush bar was included as well. The 400 came with a plug-in charger (but there are docking station contacts on the bottom of the robot), three spare filters, and a different cleaning tool. Both robots have removable debris bins at the rear, where large particles are swept into one box, and finer particles are vacuumed into another (filtered) box. Notably, the manual stresses the importance of cleaning and maintenance, and complete replacement parts are available from iRobot and other vendors.

How do they clean? They suck. No, really, they suck, and brush, and bump, and spin, and dance under and around the furniture, and into the corners, and all the little nooks and crannies. We try to keep a clean house, but the acquisition of a Scottish Terrier last year has compromised that goal. The first time we ran the 530, we stopped it half way through the cleaning cycle and checked the dirt bin. We were shocked to find a thick mat of felted dog (and human) hair in the sweeper bin, and another mat of dirt, dust, and hair in the vacuum bin. We cleaned out similar masses of debris twice more that night. We've used the robots to vacuum seven or eight times so far, and we have had similar results every time. The rotating brushes and sweepers get wrapped in hair and grunge, making the cleaning tools absolutely necessary. I intend to take very good care of my robots and use them for a long time.

The differences between the two robots are significant. The 530 ("Dirty Gertie") is smarter in how it navigates a crowded room, slowing down as it approaches an obstacle, only nudging it gently to confirm its existence. The 400 ("Fun Gus") just bumps into everything full speed ahead. Gertie is quieter and seems to finesse around carpets and loose objects on the floor with more grace, while Gus occasionally gets under the rug or stuck beneath furniture. Gertie also seems to have a little more smarts when it comes to navigating farther afield, only to find her way back to the docking station when her battery runs low. Gus is slower to find his way out of a room, and just stops when his battery is flat with a musical "Uh-Oh". They definitely have personalities, in the same way that new pets unfold once you bring them home. I look forward to working and playing with them in the future.

Dirty Gertie bumbling about the multipurpose room.